Excellence, Engineered

Built for precision, perfected through purpose.

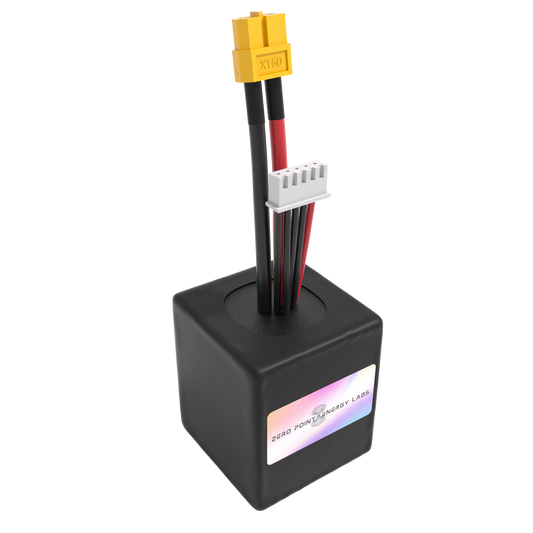

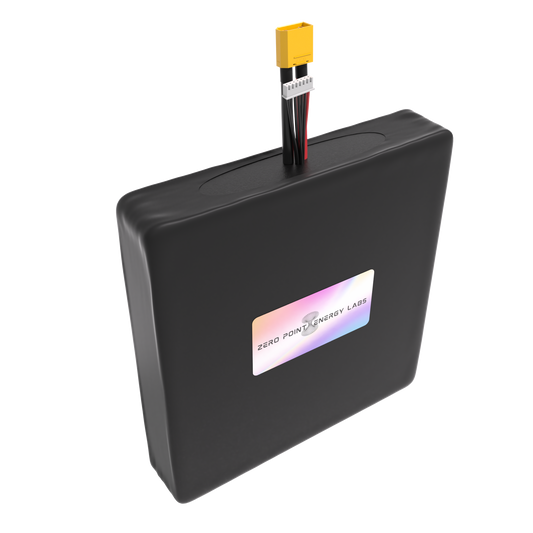

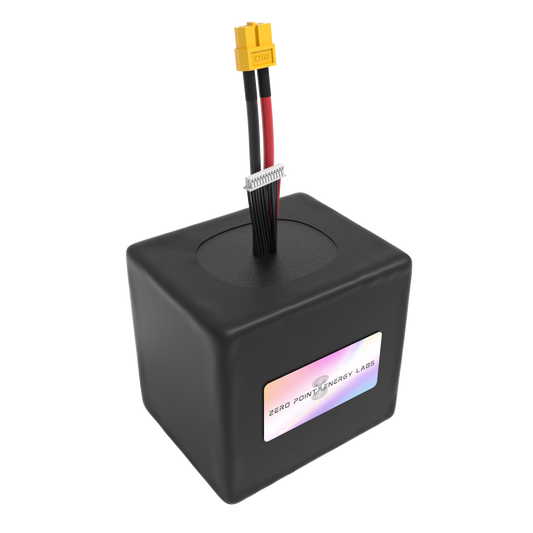

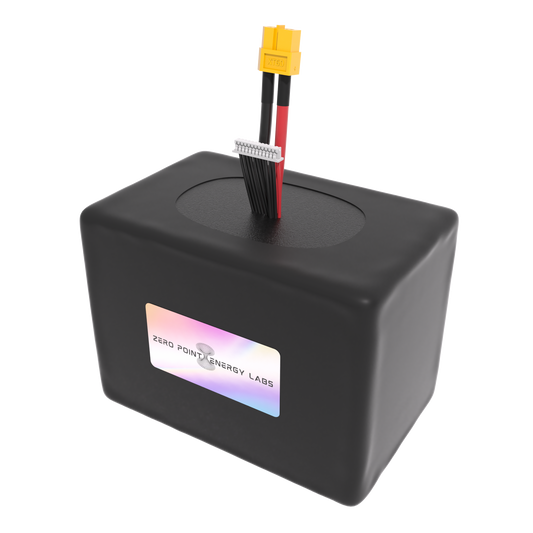

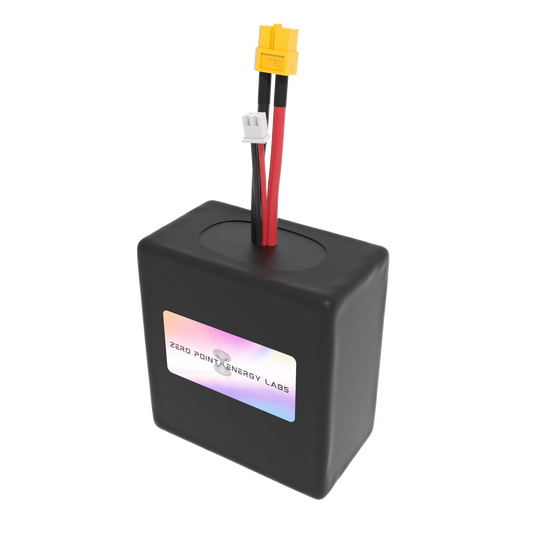

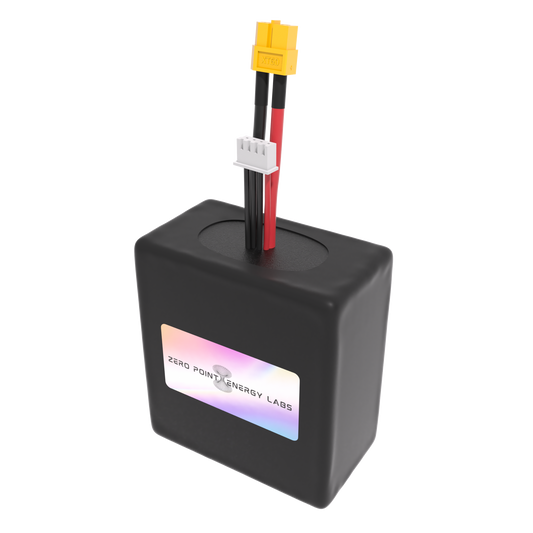

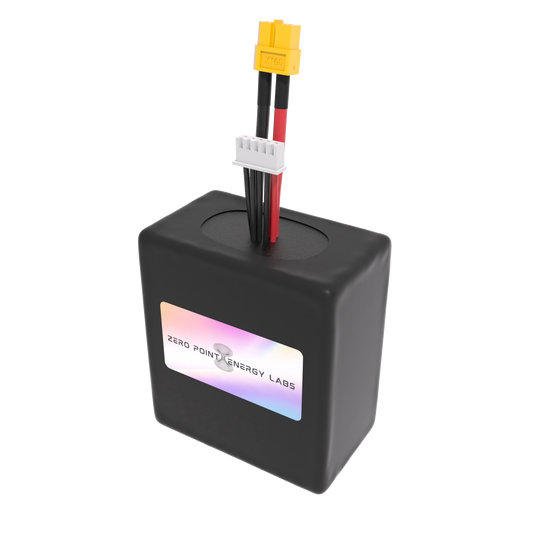

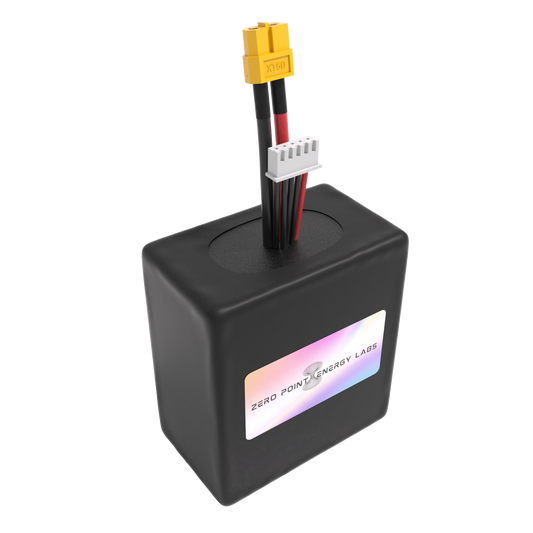

Power Systems

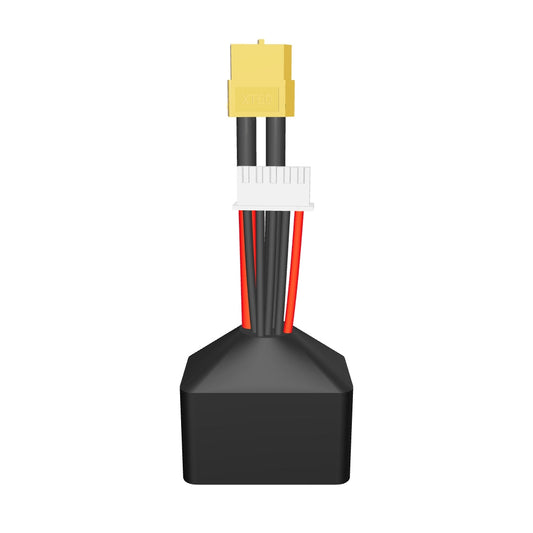

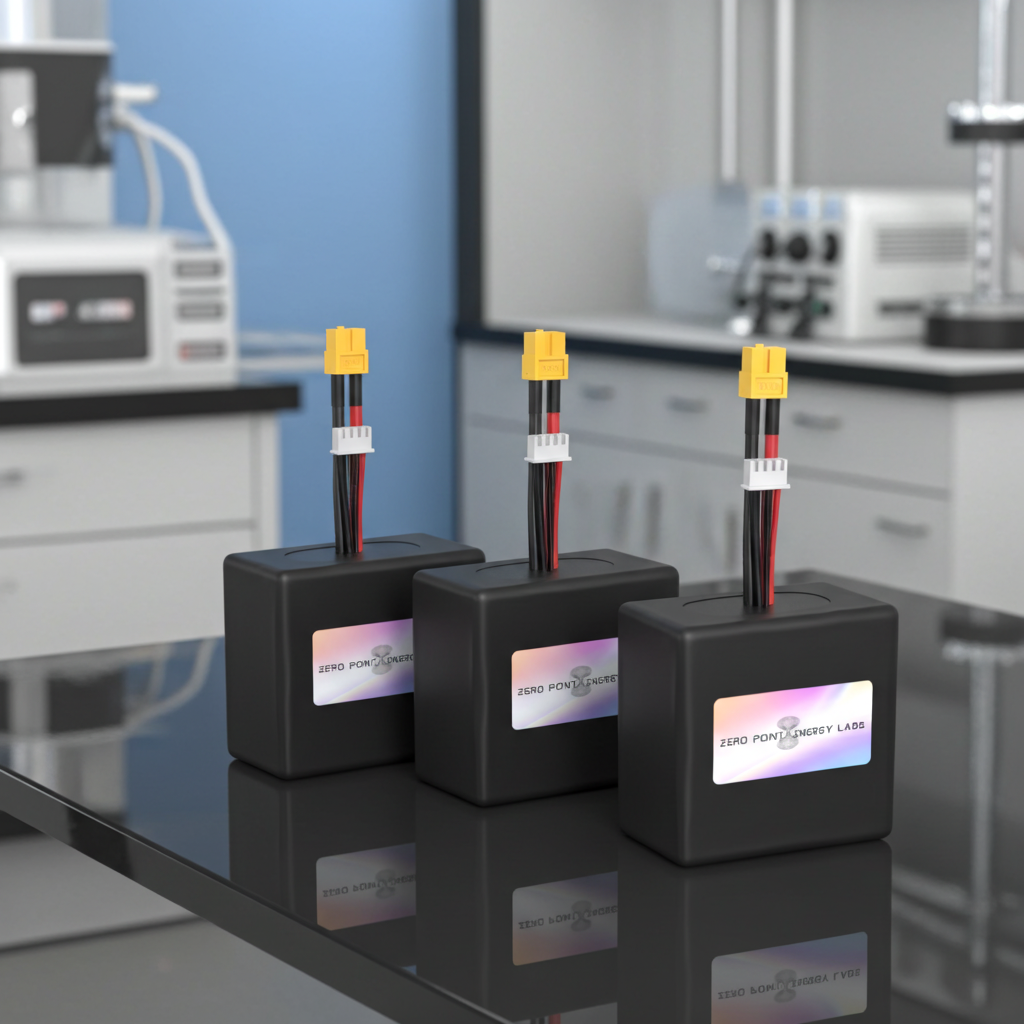

Modular Battery Packs

Power systems engineered for maximum performance, ultra-lightweight efficiency, and consistent reliability, built to operate flawlessly across demanding commercial and mission-critical environments.

Thermal Regulation

PCM Drop-In Modules

Absorb, store, and reuse heat with precision. Our custom materials regulate temperature inside battery packs, electronics, and compact devices—no fans, no fuss, just passive control where you need it.

THERMAL REGULATION

Stealth Solutions

Mask, protect, and operate without detection. Our material solutions reduce and obscure your thermal signature in the field, shielding against infrared and thermal imaging.

Applications and Industries We Support

Engineered for Performance and Reliability

-

Advanced Battery Architectures

Highest-Performing Cells on the Market

We carry the most advanced, high-energy-density cells available, lightweight, efficient, and engineered for superior discharge performance, long cycle life, and exceptional thermal stability.

Every system is designed around application-specific optimization — balancing weight, structural integrity, current capability, and thermal performance. Whether the objective is endurance, energy-to-weight optimization, or compact form factor, our pack architectures are engineered to deliver maximum performance without compromise in quality or reliability. -

Uncompromising Standards

Quality is our highest priority.

Every production batch follows a comprehensive validation workflow, including electrical characterization, thermal evaluation, continuity and insulation checks, and mechanical stability screening. Each pack is assembled in a controlled environment with precision balancing and data logging throughout the build process. Our qualification pathway ensures consistent performance, safety, and reliability aligned with industrial and defense-grade expectations.

-

Custom Laser-Cut Busbars

Optimized Current Flow

We utilize precision-laser-cut copper busbars enhanced with high-performance conductive materials, minimizing resistance and voltage drop for maximum current support. -

Thermal Intelligence

Engineered for Stability

Every module integrates advanced thermal considerations — from heat-spreading substrates to phase-change materials — ensuring consistent performance under extreme conditions. -

Certified Testing

We conduct in-house validation and collaborate with accredited partner laboratories for full UN38.3 and MIL-STD testing. These certified evaluations confirm compliance, reliability, and safety across a wide range of operational environments.

-

White Glove Support

Responsive. Precise. Customer-Focused.

Our customer service and responsiveness are unmatched.

We move quickly, communicate clearly, and remain fully committed to seeing every project through to success. Your goals are our goals — we don’t succeed until your program does. From technical coordination and system configuration to qualification support and logistics, our team ensures seamless execution, reliability, and confidence at every stage.